About QMM

QUARRY & MINING MANUFACTURE

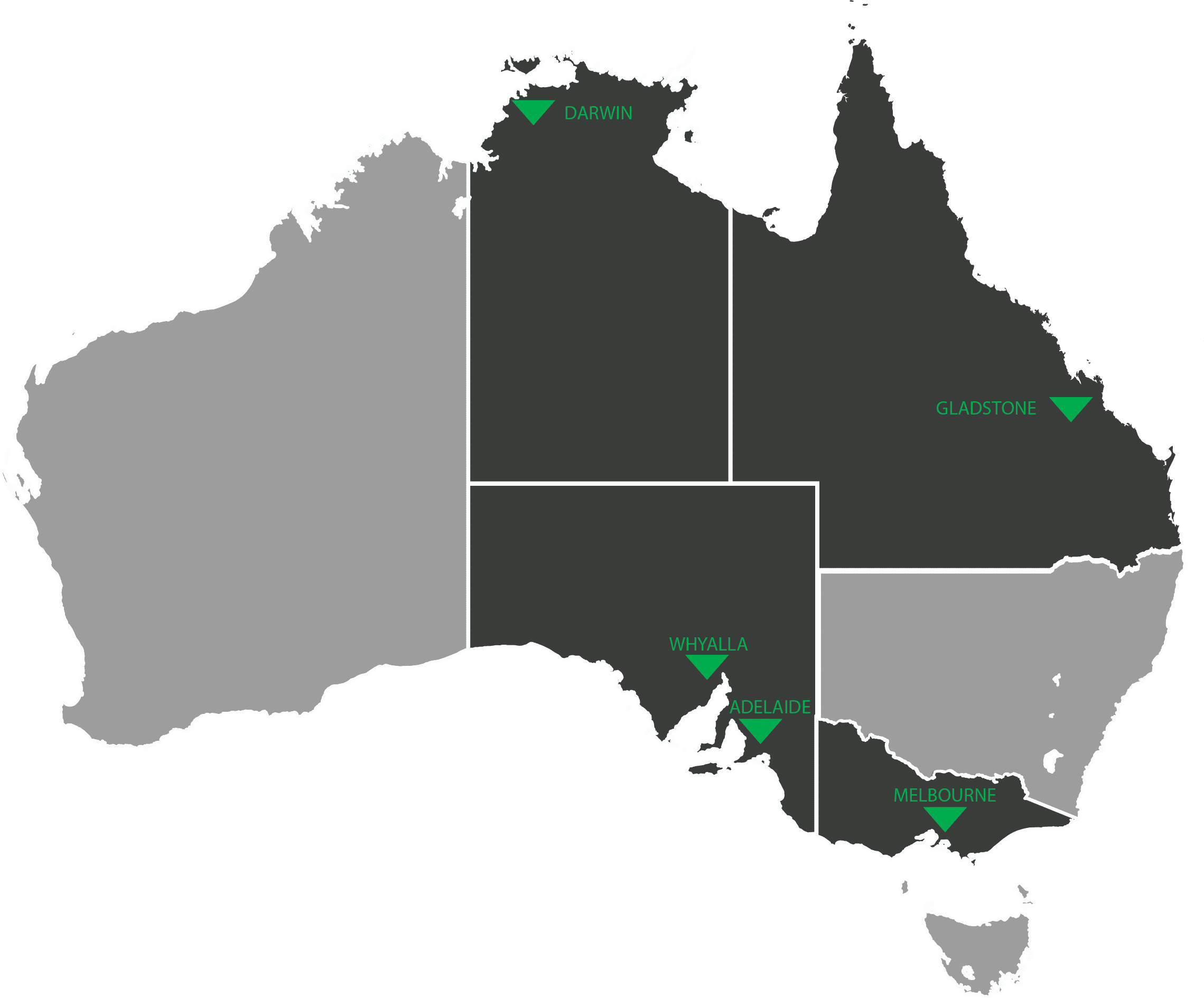

Operating across Australia, QMM, has a strong presence with premises in key locations including Adelaide, Whyalla, Darwin, Gladstone and Melbourne. With our administrative team based in Adelaide, we offer local support and the resources of a larger organisation.

QMM Industries

QMM caters a diverse range of industries, ensuring we meet the needs of various sectors. Our clientele includes Mining, Quarries, Concrete, Cement, Asphalt, Salt, Concrete Pre-Casting Moulds, Recycling, Materials Handling, and Maintenance & Repairs. By serving such a wide array of industries, we are able to provide comprehensive solutions and support across different sectors.

Safety

2023 marks 10 years of zero lost time injury days at Quarry & Mine Manufacture, and this record continues to grow. The significance of this achievement is highlighted by the nature of the industry in which QMM operates.

The 3650+ days lost time injury-free has been achieved working across various quarry, mining, and recycling sites across Australia. These sites include those controlled by; BHP Billiton, Arrium Mining, Oz Minerals, Boral, Lucas TCS, BIS Industries, Cement Australia, and more.

Certifications

The quarry, mining, recycling, and manufacturing industry operates in a high-risk environment that involves multiple contractors, crane work, heavy machinery operation, confined spaces, working at heights, and various other potential hazards.

At QMM, we take a pragmatic approach to communication and consultation, hazard and risk management, as well as risk assessment. This approach has consistently enabled us to achieve commercial and safety targets for our valued customers.

Quarry & Mining Manufacture (QMM) is a Tasmea Company.

About Tasmea Limited

Tasmea Limited is an investment company with 17 wholly owned subsidiaries that provide bespoke electrical, mechanical, civil, water and fluid services to the Mining, Defence, Water, Energy and Financial sectors.

To learn more about Tasmea Limited and its subsidiaries, visit the website.